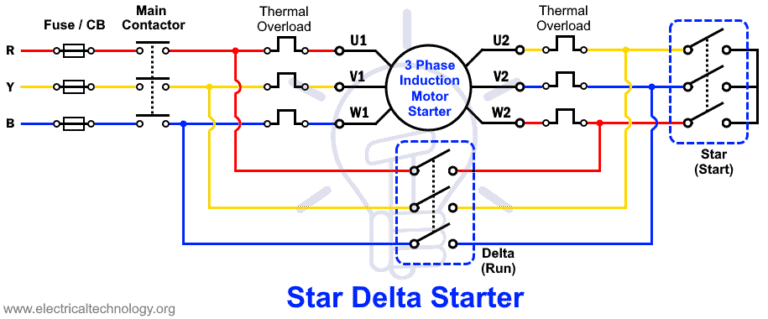

- Introduction: A star-delta starter is primarily used for starting and controlling three-phase induction motors. It provides a method to reduce the starting current and torque during motor startup, minimizing the impact on the power supply.

- Components: A star-delta starter typically consists of the following components:

- Contactor: The contactor is an electromechanical switch that connects and disconnects the motor windings to the power supply.

- Timer: The timer controls the switching operation between the star and delta configurations. It introduces a delay to ensure proper motor acceleration before transitioning from star to delta.

- Motor Windings: The motor windings are arranged in three sets and are connected in either a star or delta configuration.

- Star Configuration: During motor startup, the star-delta starter initially connects the motor windings in a star configuration. In the star configuration, the voltage applied to each winding is reduced, thereby limiting the starting current.

- Delta Configuration: Once the motor reaches a certain speed, the windings are switched to a delta configuration. In the delta configuration, the windings receive the full voltage, enabling the motor to operate at maximum torque.

- Timer Control: The transition from the star to the delta configuration is controlled by a timer. The timer introduces a delay between switching operations, allowing the motor to accelerate in the star configuration before the switch to delta.

- Suitable for Larger Motors: Star-delta starters are commonly used for larger induction motors, typically above 5 horsepower. They are particularly beneficial in applications where the starting current needs to be limited to prevent voltage drops and electrical disturbances in the power supply.

- Limitations: While star-delta starters provide efficient motor startup and control, they are not suitable for variable speed control or advanced motor control features. They are primarily designed for simple motor starting applications.

- In summary, star-delta starters offer a solution to reduce the starting current and torque of three-phase induction motors, ensuring a smooth and controlled startup. They are commonly used for larger motors but have limitations in terms of advanced motor control capabilities.

Visit our website at Dhatascient – Engineering Services, Analytics and Trainings to learn more about our services and how we can assist your organization with your switchgear LV and MV needs.

📧team@dhatascient.com

📞+91 8778297667

🌐www.dhatascient.com